Here's the web site URL https://www.wencerl.com. Wencerl is a leading company of

Finish Mills: Functional Tools for Exact Material Removal

Square Close Mills: Perfect for generating sharp corners and flat-bottomed cavities. Ball Nose Conclusion Mills : Ideal for 3D contouring and sculpting sophisticated surfaces.Corner Radius End Mills: Combine the characteristics of sq. and ball nose mills for extra energy and versatility. Roughing Conclude Mills: Designed for swift materials elimination with small heat technology. Ending Stop Mills: Give clean finishes and limited tolerances in delicate operations.

end mill holder

Milling Resources: Essential Elements for Successful Milling Operations

- Facial area Mills: Employed for machining flat surfaces and making a fantastic finish.

Shell Mills : Versatile tools that can be used for each roughing and finishing functions.Slab Mills: Suited to getting rid of large quantities of fabric through the workpiece. End Mills: Supply flexibility in slicing a variety of supplies and styles. Fly Cutters : Supply a Charge-efficient Option for achieving a smooth surface finish.

Resource Holders: Guaranteeing Balance and Precision in Machining

Collet Chucks: Provide high clamping force and are ideal for Keeping compact-diameter instruments. Conclude Mill Holders: Meant to securely maintain stop mills and lessen Software runout. Shell Mill Arbors: Used to mount shell mills on to the device spindle. Drill Chucks : Let for speedy modifications involving drills and other applications.- Rapid Modify Instrument Posts: Enable swift Instrument changes, lessening downtime in CNC functions.

Precision Chopping Resources: Attaining High Precision in Machining

Carbide Equipment: Supply great hardness and put on resistance for extended Resource life. Cermet Instruments: Deliver top-quality surface complete and are perfect for substantial-pace machining. Higher-Speed Metal (HSS) Instruments: Functional and price-powerful, well suited for a wide range of apps. Ceramic Tools: Capable of withstanding high temperatures and so are useful for tough product machining. Polycrystalline Diamond (PCD) Tools: Present Excellent wear resistance for machining non-ferrous resources.

Threading Applications: Building Internal and External Threads with Precision

Thread Mills: Employed for developing interior and external threads with substantial accuracy. Faucet Drills : Present the proper gap dimension for tapping functions.- Die Heads: Allow for for rapid and exact thread chopping in guide operations.

Threading Inserts: Replaceable chopping edges for economical thread manufacturing. Chasers: Utilized in lathes for reducing threads on cylindrical workpieces.

Drilling Applications: Important for Producing Holes in A variety of Materials

Twist Drills : Generally employed for drilling holes in metallic, Wooden, and plastic.Heart Drills: Made use of to create a conical gap for accurate centering of your workpiece. Move Drills: Allow for drilling many gap sizes without transforming equipment. Spade Drills: Suited to deep hole drilling with superior product removal fees. Gun Drills: Designed for precision drilling of deep holes with modest diameters.

Turning Applications: Shaping Components with Rotational Movement

Turning Inserts: Replaceable chopping edges for turning operations. Parting Applications: Used to Minimize off sections of the workpiece in the course of turning. Monotonous Bars : Make it possible for for inside diameter machining with substantial precision.- Grooving Tools: Create grooves and slots from the workpiece.

Knurling Resources : Generate textured patterns on cylindrical surfaces for improved grip.

Reducing Instrument Products: Picking out the Proper Material to the Position

- Significant-Velocity Steel (HSS): Gives excellent toughness and is also appropriate for common-function machining.

- Cemented Carbide: Provides large hardness and don resistance for extended tool lifetime.

Cermet: Combines ceramic and metallic components for improved surface area complete. Ceramic: Capable of withstanding significant temperatures for machining challenging components. Polycrystalline Diamond (PCD) : Provides exceptional dress in resistance for non-ferrous materials machining.

Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Andrew Keegan Then & Now!

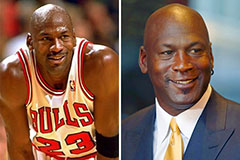

Andrew Keegan Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!