Here's the web site URL https://www.wencerl.com. Wencerl is a number one provider of

Stop Mills: Multipurpose Resources for Exact Materials Removing

Sq. End Mills : Perfect for making sharp corners and flat-bottomed cavities.Ball Nose Conclude Mills: Ideal for 3D contouring and sculpting complex surfaces. Corner Radius Finish Mills: Mix the functions of sq. and ball nose mills for included toughness and flexibility. - Roughing Conclusion Mills: Created for fast material removal with minimal heat era.

Finishing Conclude Mills : Present sleek finishes and tight tolerances in fragile operations.

Milling Instruments: Critical Factors for Productive Milling Operations

Face Mills: Utilized for machining flat surfaces and creating a high-quality complete. Shell Mills: Multipurpose instruments that may be useful for both equally roughing and ending functions. Slab Mills: Appropriate for eliminating significant quantities of fabric from the workpiece. Close Mills: Offer you overall flexibility in slicing numerous components and shapes. - Fly Cutters: Supply a Price-efficient Resolution for achieving a clean surface area finish.

tool holder

Resource Holders: Making certain Stability and Precision in Machining

Collet Chucks: Deliver substantial clamping pressure and are ideal for Keeping compact-diameter equipment. Close Mill Holders : Made to securely keep conclusion mills and decrease Instrument runout.- Shell Mill Arbors: Utilized to mount shell mills onto the machine spindle.

Drill Chucks: Allow for for rapid adjustments concerning drills and other instruments. Speedy Alter Resource Posts: Help immediate Resource adjustments, minimizing downtime in CNC functions.

Precision Chopping Resources: Reaching Large Precision in Machining

Carbide Equipment : Offer great hardness and put on resistance for extended Instrument existence.Cermet Applications : Give excellent area finish and are ideal for higher-velocity machining.Large-Speed Steel (HSS) Resources : Versatile and cost-powerful, suitable for a wide array of applications.Ceramic Tools: Able to withstanding large temperatures and are utilized for challenging material machining. Polycrystalline Diamond (PCD) Tools : Give Fantastic use resistance for machining non-ferrous supplies.

Threading Instruments: Generating Internal and External Threads with Precision

Thread Mills: Employed for making internal and external threads with substantial accuracy. Faucet Drills: Supply the right hole measurement for tapping functions. Die Heads: Allow for fast and precise thread slicing in guide operations. - Threading Inserts: Replaceable chopping edges for productive thread production.

- Chasers: Employed in lathes for reducing threads on cylindrical workpieces.

Drilling Equipment: Important for Developing Holes in Several Supplies

Twist Drills : Frequently employed for drilling holes in metal, wood, and plastic.Middle Drills : Made use of to produce a conical gap for correct centering in the workpiece.Move Drills: Allow for drilling multiple hole sizes devoid of transforming instruments. Spade Drills: Ideal for deep hole drilling with significant materials elimination fees. Gun Drills: Suitable for precision drilling of deep holes with little diameters.

Turning Instruments: Shaping Resources with Rotational Movement

Turning Inserts: Replaceable chopping edges for turning operations. - Parting Applications: Utilized to Slash off sections of a workpiece all through turning.

Dull Bars: Allow for inner diameter machining with higher precision. Grooving Resources: Produce grooves and slots while in the workpiece. Knurling Applications : Deliver textured designs on cylindrical surfaces for enhanced grip.

Reducing Device Elements: Selecting the Proper Content for your Job

Significant-Velocity Metal (HSS) : Offers very good toughness and is also suitable for standard-function machining.Cemented Carbide : Provides higher hardness and don resistance for extended tool existence.- Cermet: Combines ceramic and metallic elements for improved floor complete.

Ceramic : Capable of withstanding higher temperatures for machining hard materials.Polycrystalline Diamond (PCD) : Features Outstanding don resistance for non-ferrous materials machining.

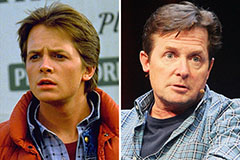

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!