Here is the web site URL https://www.wencerl.com. Wencerl is a leading service provider of

Stop Mills: Flexible Tools for Precise Product Elimination

Square Conclusion Mills: Perfect for making sharp corners and flat-bottomed cavities. Ball Nose Conclude Mills: Ideal for 3D contouring and sculpting intricate surfaces. - Corner Radius End Mills: Mix the functions of square and ball nose mills for included strength and flexibility.

- Roughing Finish Mills: Created for immediate materials elimination with minimum heat generation.

Finishing Close Mills: Provide smooth finishes and limited tolerances in fragile operations.

Milling Resources: Vital Elements for Effective Milling Functions

- Confront Mills: Useful for machining flat surfaces and generating a fine complete.

Shell Mills: Adaptable tools that may be employed for the two roughing and finishing functions. Slab Mills : Well suited for taking away significant quantities of material through the workpiece.Conclude Mills: Present flexibility in cutting various elements and shapes. Fly Cutters: Supply a Price-helpful Remedy for achieving a easy area complete.

threading tool holder

Device Holders: Ensuring Steadiness and Precision in Machining

Collet Chucks : Present higher clamping drive and are perfect for holding tiny-diameter applications.Conclude Mill Holders: Designed to securely keep conclude mills and lower Software runout. Shell Mill Arbors : Accustomed to mount shell mills on to the device spindle.Drill Chucks : Let for swift adjustments between drills together with other resources.Brief Adjust Tool Posts : Permit speedy Resource improvements, decreasing downtime in CNC operations.

Precision Cutting Equipment: Accomplishing Substantial Accuracy in Machining

Carbide Equipment: Give outstanding hardness and don resistance for extended tool everyday living. - Cermet Equipment: Offer remarkable surface end and are ideal for superior-velocity machining.

Large-Pace Steel (HSS) Resources : Versatile and value-efficient, ideal for a wide array of apps.- Ceramic Tools: Effective at withstanding high temperatures and are used for hard material machining.

- Polycrystalline Diamond (PCD) Tools: Supply Outstanding use resistance for machining non-ferrous supplies.

Threading Tools: Producing Inside and Exterior Threads with Precision

Thread Mills: Used for producing inner and exterior threads with substantial precision. - Faucet Drills: Provide the right hole dimensions for tapping operations.

Die Heads : Allow for brief and precise thread chopping in guide operations.Threading Inserts : Replaceable cutting edges for productive thread creation.Chasers: Utilized in lathes for cutting threads on cylindrical workpieces.

Drilling Resources: Essential for Generating Holes in Numerous Resources

Twist Drills: Typically useful for drilling holes in metallic, Wooden, and plastic. Middle Drills : Utilized to produce a conical hole for correct centering of your workpiece.Move Drills: Make it possible for for drilling numerous hole measurements without altering instruments. Spade Drills: Well suited for deep hole drilling with superior product removing fees. - Gun Drills: Designed for precision drilling of deep holes with modest diameters.

Turning Tools: Shaping Resources with Rotational Movement

Turning Inserts : Replaceable slicing edges for turning functions.- Parting Tools: Used to Slash off sections of a workpiece in the course of turning.

Tedious Bars: Enable for interior diameter machining with high precision. Grooving Equipment: Make grooves and slots while in the workpiece. Knurling Instruments: Generate textured designs on cylindrical surfaces for improved grip.

Slicing Tool Supplies: Picking out the Correct Content with the Position

High-Velocity Steel (HSS) : Features great toughness and is also ideal for basic-objective machining.Cemented Carbide : Offers substantial hardness and use resistance for extended Software lifetime.- Cermet: Combines ceramic and metallic materials for enhanced surface finish.

Ceramic : Effective at withstanding significant temperatures for machining challenging resources.Polycrystalline Diamond (PCD): Features Fantastic use resistance for non-ferrous product machining.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Danica McKellar Then & Now!

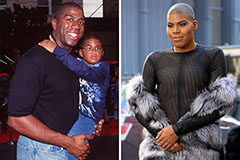

Danica McKellar Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Lucy Lawless Then & Now!

Lucy Lawless Then & Now!