Here's the web site URL https://www.wencerl.com. Wencerl is a leading provider of

Conclusion Mills: Versatile Resources for Exact Material Elimination

Square Close Mills: Ideal for developing sharp corners and flat-bottomed cavities. Ball Nose Conclude Mills : Great for 3D contouring and sculpting complex surfaces.Corner Radius Conclusion Mills: Blend the characteristics of sq. and ball nose mills for added toughness and flexibility. Roughing Finish Mills: Designed for swift substance removal with minimal heat generation. Ending Conclusion Mills : Give sleek finishes and restricted tolerances in sensitive functions.

fast machining

Milling Equipment: Vital Factors for Efficient Milling Operations

Experience Mills : Used for machining flat surfaces and creating a high-quality end.Shell Mills : Versatile instruments that may be useful for the two roughing and ending functions.Slab Mills: Suitable for removing big amounts of material within the workpiece. Conclusion Mills : Give flexibility in cutting different elements and styles.Fly Cutters: Provide a Price-successful solution for accomplishing a sleek floor complete.

Software Holders: Guaranteeing Steadiness and Precision in Machining

Collet Chucks: Deliver substantial clamping pressure and are perfect for holding smaller-diameter tools. Finish Mill Holders: Meant to securely maintain close mills and reduce Software runout. - Shell Mill Arbors: Utilized to mount shell mills on to the machine spindle.

Drill Chucks: Allow for for swift improvements among drills and also other resources. Quick Transform Instrument Posts: Allow fast Software adjustments, cutting down downtime in CNC operations.

Precision Slicing Resources: Achieving Significant Accuracy in Machining

Carbide Tools: Offer you outstanding hardness and use resistance for prolonged Device existence. Cermet Tools: Give outstanding area complete and are ideal for significant-pace machining. Large-Speed Steel (HSS) Instruments : Flexible and price-efficient, ideal for a wide range of purposes.Ceramic Tools : Capable of withstanding higher temperatures and they are employed for hard materials machining.Polycrystalline Diamond (PCD) Applications : Offer you Remarkable use resistance for machining non-ferrous elements.

Threading Resources: Building Inside and External Threads with Precision

Thread Mills: Employed for producing inner and exterior threads with significant precision. Faucet Drills: Present the right hole sizing for tapping operations. - Die Heads: Allow for fast and precise thread slicing in manual functions.

Threading Inserts: Replaceable reducing edges for successful thread creation. Chasers : Used in lathes for reducing threads on cylindrical workpieces.

Drilling Resources: Important for Creating Holes in Various Products

Twist Drills: Typically used for drilling holes in metallic, Wooden, and plastic. Heart Drills: Utilized to make a conical gap for accurate centering of your workpiece. Stage Drills : Let for drilling many gap measurements without having changing applications.Spade Drills: Well suited for deep gap drilling with significant substance elimination prices. Gun Drills: Suitable for precision drilling of deep holes with compact diameters.

Turning Applications: Shaping Resources with Rotational Movement

Turning Inserts: Replaceable chopping edges for turning functions. Parting Applications: Used to Reduce off sections of the workpiece all through turning. Uninteresting Bars: Permit for interior diameter machining with high precision. Grooving Tools: Make grooves and slots while in the workpiece. Knurling Equipment: Make textured patterns on cylindrical surfaces for enhanced grip.

Slicing Instrument Materials: Selecting the Correct Substance for the Work

High-Pace Metal (HSS): Presents superior toughness and is suitable for normal-objective machining. Cemented Carbide: Provides significant hardness and put on resistance for prolonged Instrument life. Cermet: Combines ceramic and metallic resources for improved surface area finish. Ceramic: Able to withstanding superior temperatures for machining difficult elements. Polycrystalline Diamond (PCD): Provides Fantastic use resistance for non-ferrous substance machining.

Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Elin Nordegren Then & Now!

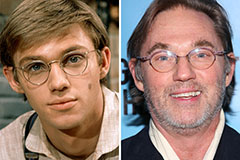

Elin Nordegren Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!